Choosing the right binding solution for your printing projects can be a challenge, and usually, the type of binding selected is based on the function of the printed material and the number of sheets the document has and of course the printing budget. Unless quality is a priority and budget is higher than normal or the binding itself is part of the conceptual design, then strangely aesthetic appeal the binding gives is last on the list of factors, when making a decision. It shouldn’t really be this way around, the correct binding finishes off your perfect printed material, it shows quality, differentiates from competition and will maintain a quality document through use.

So how do you decide, we have put together some technical specifications about binding so you can find your way around the print and Print Finishing industry and we have collated some of the best bindings in design so you can see it from all angles before making a decision.

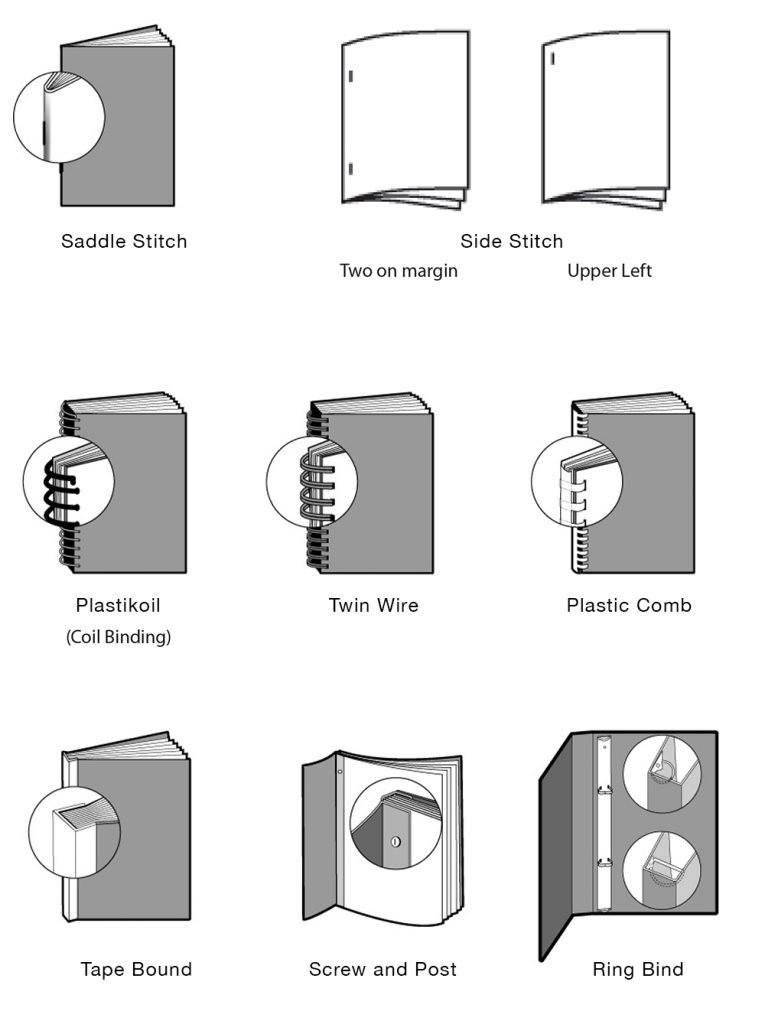

Saddle Stitching

Probably the most common and economical binding method. Created by punching wire through the document’s outside spine, then bending the wire flat on the inside centrefold to grip all the pages. It may provide a similar look, but is not the same as stapling.

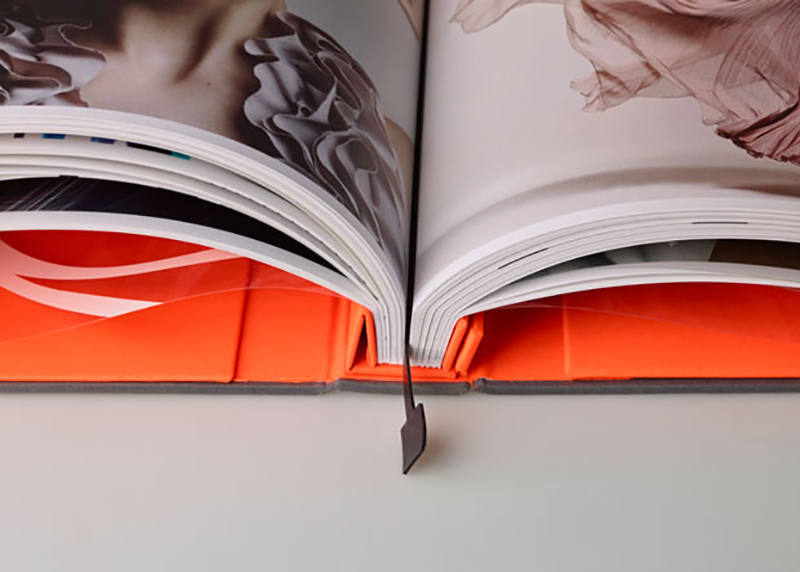

Perfect Bound

Sections of folded pages (signatures) have their spines trimmed off and roughed up to improve bonding with glue. All sections are collated and glued to its wrap-around cover. The cover is always scored on back and front, for ease of opening and less stress on the spine.

Tape Bound

This method involves an adhesive tape being wrapped around the spine to hold the covers and inside pages in place. Usually, pages need to be stitched together prior to affixing the tape to reinforce and provide added strength.

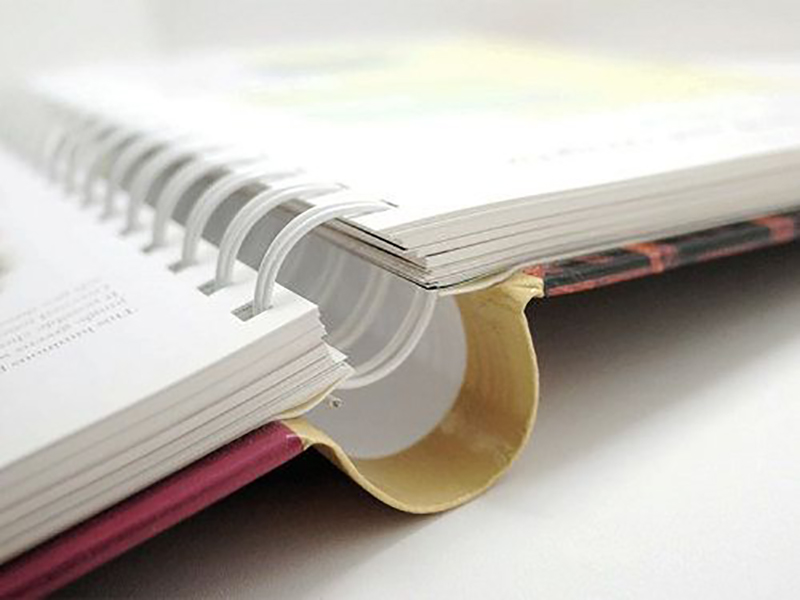

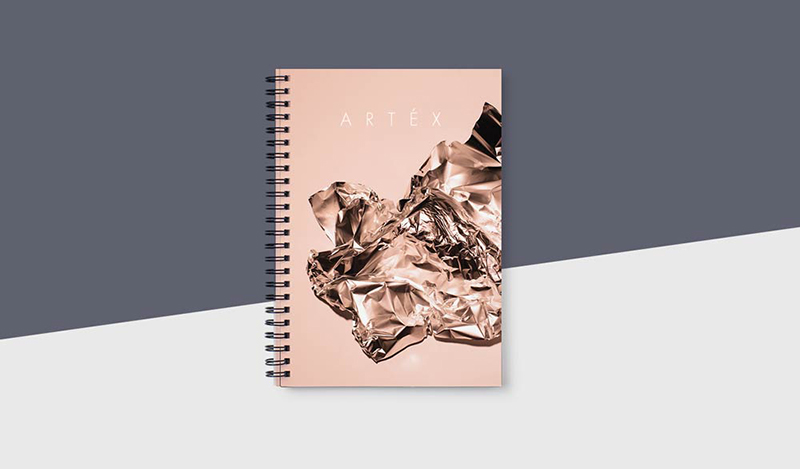

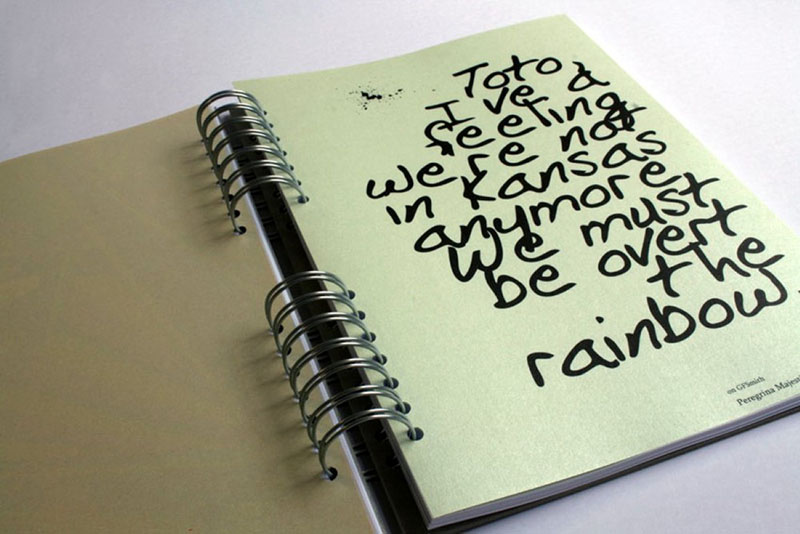

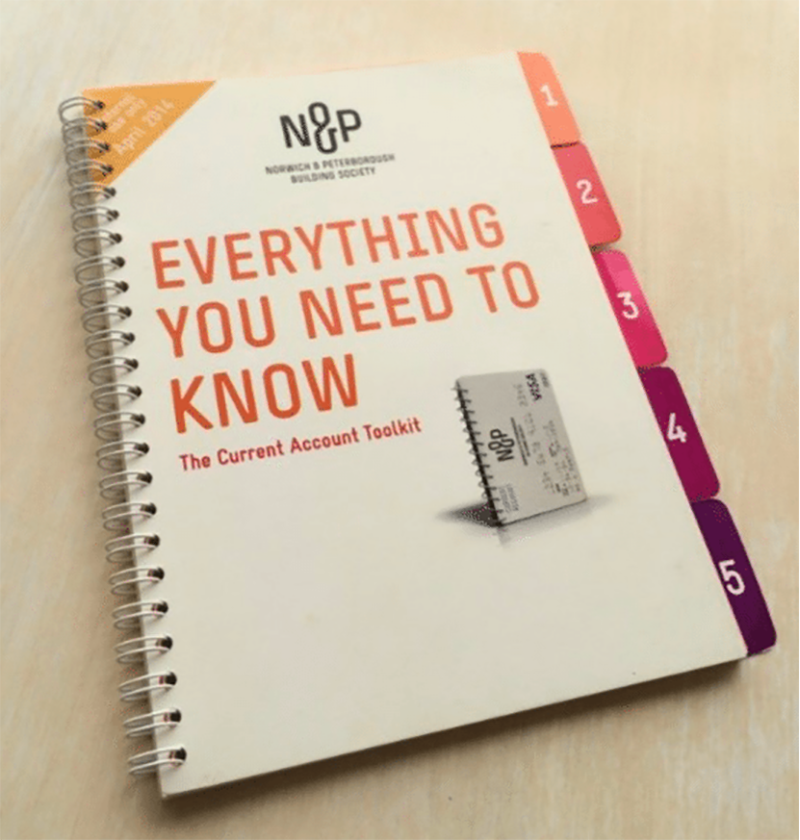

Twin Wire Bound

Highly popular Wire bind option uses formed wire that is inserted through punched holes. This allows books to lay flat when open. Wire loops are available in a variety of colours and sizes to coordinate with cover colour. An economical, efficient and durable option for a wide variety of project types.

Plastikoil Bound

Utilizes a smooth round coil to hold pages together. Allows book to lie flat when open or pages can be turned all the way around to the back if desired. The plastic coil is threaded through punched holes and then ends are crimped to prevent the coil from slipping off. Spirals or coils are available in a variety of colours and sizes.

Screw Bound

In screw, stud or post binding, first holes are drilled through the complete document. Then a barrel post is inserted through the holes and a cap screw is added to the post to hold everything together. Frequently used for swatch books.

Plastic Comb Bound

An economical method is suitable for manuals and books that need to lay flat when open. Using rectangular holes punched through the document, the plastic combs rings are threaded through holes. Page edges at spine are covered by the plastic comb.

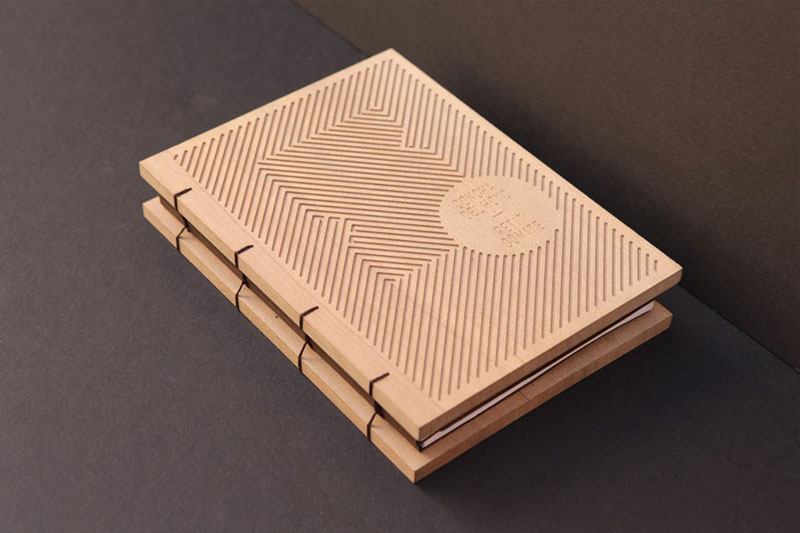

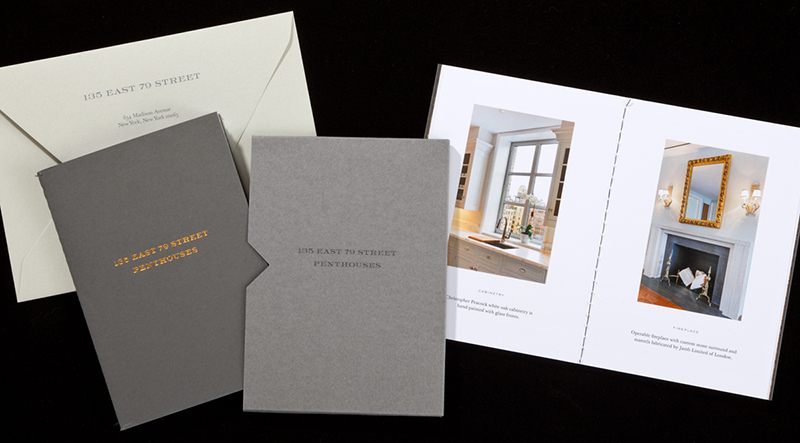

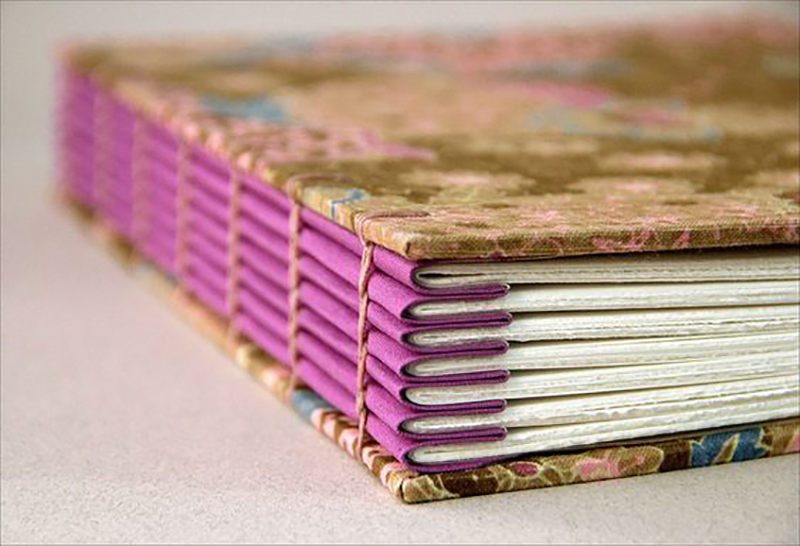

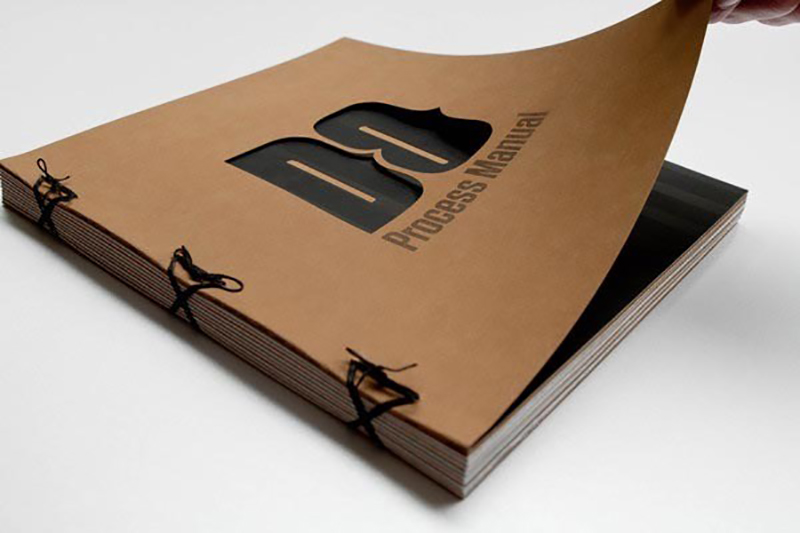

What about design aesthetic

Now that we have gone through the technical jargon of binding options, what about the design element when binding, the innovation to lift printed materials and the thought behind a well-executed design. The finish you give your end product and catches the eye of consumers is thoroughly important and keeps the client coming back to your annual report, catalogue, brochure and company profile. The touch, feel and usability is something that should be added into the budget, to give that perfect bound printed material.

Here are some of our favourites we found:

You must be logged in to post a comment.