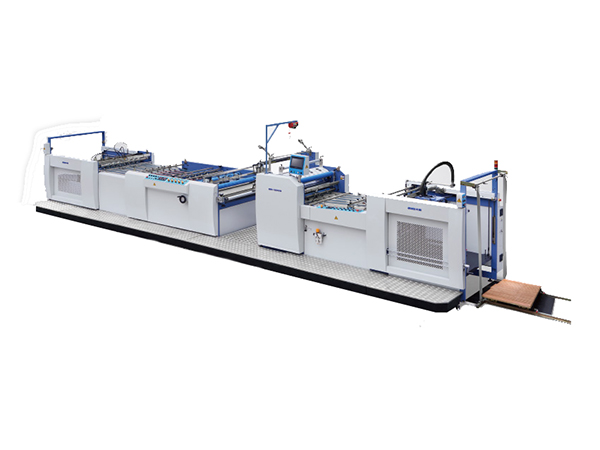

Description

- Overlapping regulator: the Servo Control and Front Lay regulator guarantee accuracy of paper overlapping.

- Smart consistent temperature heating roller: with the built-in oil heater, temperature measuring sensor and temperature controller, the machine ensures the temperature is stable and consistent at all times.

- The film shaft is controlled by pneumatic pressure which allows easy change over and adjusting of laminating film rolls.

- Anti-curl device: The machine is equipped with an anti-curl device, which ensures that paper remains flat, and smooth during the lamination process.

- Electrical system: Schneider PLC Inverter, Omron Electrics and other international parts make for a smooth running machine that is easily adjustable to required settings.

- Equipped with a Flying Knife, pneumatic perforating device and photoelectrical detector to rapidly separate the paper according to the paper size.

- After separation the laminated sheets are collected by the paper jogger keeping the sheets in order.

- The Servo controller and Side Lay Mechanism guarantees precise paper alignment at all times.

- A user-friendly interface system with a colour screen simplifies the operation process. The operator can easily check the status at any given time.

- The pneumatic stacker receives the paper, keeping them in order, while rapidly counting every sheet.

- Equipped with a paper pre-stacker, Servo controlled feeder and a photoelectric sensor to ensure that paper is continuously fed into the machine.

- Maximum Paper Size: 1050 x 1200mm

- Minimum Paper Size: 350 x 350mm

- Paper Thickness: 100-500g/m2

- Laminating Speed: 0-120m/min

- Gross Power: 30KW

- Total Weight: 5000kg

- Overall Dimensions: 117700 x 2200 x 1900mm